Why Glass Pad Die Cutting Machines are Revolutionizing Post-Processing in Manufacturing

Why Glass Pad Die Cutting Machines are Revolutionizing Post-Processing

Introduction to Die Cutting Technology

The world of manufacturing constantly evolves, with technological advancements paving the way for improved efficiency and precision. Among the numerous innovations, **glass pad die cutting machines** stand out as a transformative force in post-processing. These machines utilize advanced technology to achieve high levels of accuracy and speed, radically changing how materials are cut and processed.

In this article, we will explore the various aspects of glass pad die cutting machines, their advantages over traditional methods, and their growing significance in the manufacturing sector.

The Mechanics of Glass Pad Die Cutting Machines

How Glass Pad Die Cutting Works

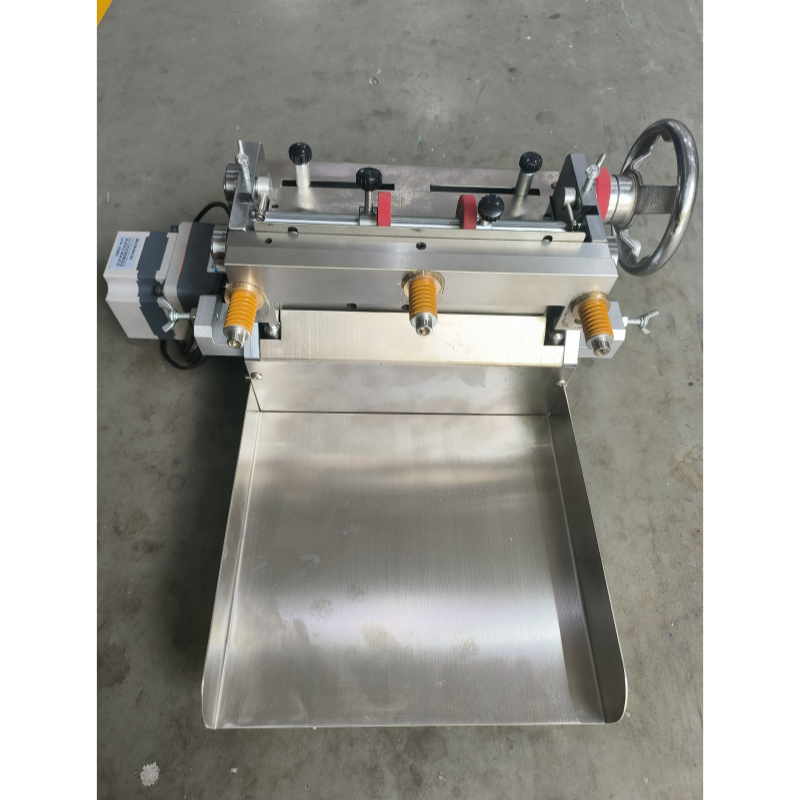

Glass pad die cutting machines operate on a simple yet effective principle. They utilize a die—often made from steel or other durable materials—to cut through various substrates with unparalleled precision. The glass pad serves as a rigid surface that provides stability during the cutting process, ensuring that the die can apply consistent pressure across the material.

When the die comes into contact with the substrate, the combination of sharp edges and pressurized force allows for clean cuts without fraying or tearing, which is often a problem with traditional cutting methods. This mechanism not only enhances precision but also reduces waste, making it a cost-effective solution for manufacturers.

Key Components of Glass Pad Die Cutting Machines

Understanding the key components of these machines can shed light on their functionality:

1. **Die**: The heart of the cutting process, available in various shapes and sizes, tailored to specific applications.

2. **Glass Pad**: A stable cutting surface that supports the material during the cutting process.

3. **Press Mechanism**: This can be hydraulic, pneumatic, or mechanical, providing the necessary force to drive the die into the material.

4. **Control System**: Modern machines come equipped with computerized controls for programmable settings, enhancing user interaction and operational efficiency.

Advantages of Glass Pad Die Cutting Machines

Enhanced Precision and Quality

One of the standout features of glass pad die cutting machines is their ability to deliver **unmatched precision**. The flat and stable nature of the glass pad ensures that each cut is consistent and accurate, drastically reducing the variation often seen in traditional methods. This level of quality is essential in industries that require intricate designs and sharp details, such as packaging, automotive, and textiles.

Increased Efficiency and Speed

Time is a crucial factor in manufacturing, and glass pad die cutting machines excel in this area. They can process large volumes of material in a shorter timeframe compared to conventional cutting methods. The combination of speed and precision not only boosts productivity but also enables manufacturers to meet tight deadlines without compromising quality.

Versatility Across Industries

Glass pad die cutting machines are incredibly versatile, accommodating a wide range of materials including paper, cardboard, plastics, and even textiles. This adaptability makes them invaluable in various sectors such as:

- **Packaging**: Creating custom packaging solutions with intricate designs and shapes.

- **Textiles**: Cutting fabrics for garments and upholstery with precision.

- **Automotive**: Producing components that require exact specifications for functionality and safety.

Applications of Glass Pad Die Cutting Machines

Custom Packaging Solutions

In the packaging industry, the demand for custom solutions is ever-growing. Glass pad die cutting machines can create specialized designs that enhance product visibility and brand identity. This capability allows manufacturers to cater to the unique needs of their clients, whether it be for retail packaging, shipping boxes, or promotional materials.

Textile Industry Innovations

The textile industry benefits immensely from the precision offered by glass pad die cutting machines. These machines streamline the cutting process, allowing for intricate patterns and shapes to be produced efficiently. This efficiency translates to reduced fabric waste and lower production costs, making it a win-win for manufacturers and consumers alike.

Automotive Parts Production

In the automotive sector, precise components are crucial for safety and performance. Glass pad die cutting machines ensure that parts are manufactured to exact specifications, which is vital for meeting regulatory standards and ensuring vehicle safety.

The Future of Glass Pad Die Cutting Machines

Technological Advancements on the Horizon

As technology continues to advance, we can expect glass pad die cutting machines to evolve further. Innovations such as AI-driven automation and improved material handling systems are on the horizon, promising to enhance operational efficiency even more. These advancements will open new avenues for manufacturers, allowing them to push the boundaries of design and functionality.

Sustainability in Manufacturing

With growing concerns about environmental impact, the manufacturing industry is moving towards sustainable practices. Glass pad die cutting machines contribute to sustainability by reducing material waste and enabling the use of eco-friendly substrates. As companies strive to minimize their carbon footprint, these machines will play a pivotal role in achieving those goals.

Frequently Asked Questions (FAQs)

1. What materials can be cut using glass pad die cutting machines?

Glass pad die cutting machines can effectively cut a variety of materials, including paper, cardboard, plastics, and textiles.

2. How do glass pad die cutting machines compare to traditional die cutting methods?

They offer enhanced precision, increased efficiency, and reduced material waste compared to traditional methods.

3. What industries benefit most from glass pad die cutting machines?

Industries such as packaging, textiles, and automotive significantly benefit from the precision and versatility of these machines.

4. Are glass pad die cutting machines suitable for small-scale production?

Yes, they can be tailored to suit both small-scale and large-scale production needs, making them versatile for various operations.

5. What is the typical lifespan of a glass pad die cutting machine?

With proper maintenance, a glass pad die cutting machine can last several years, providing consistent performance throughout its lifespan.

Conclusion

In conclusion, glass pad die cutting machines are revolutionizing the post-processing landscape in manufacturing. Their ability to deliver precision, speed, and versatility makes them indispensable tools in various industries. As technology advances and the demand for sustainable practices grows, the significance of these machines will only increase. Manufacturers that adopt glass pad die cutting technology position themselves to thrive in an increasingly competitive market, ensuring they meet the evolving needs of their customers while maintaining high standards of quality and efficiency. Embracing this innovative technology today sets the stage for a more productive and sustainable manufacturing future.

About Us

Specializing in the production of automatic stamping equipment and punching machine peripheral equipment, is a research and development, design, production, sales, maintenance as one of the international precision stamping automation equipment manufacturing enterprises.

Contact Us

Add: Building A, Xiaoxuewei Industrial Park, Shajing, Bao'an District, Shenzhen

WhatsApp: +86 190 9240 6289

E-mail: xiaolisisale1@gmail.com

Related News