Understanding Foot Mat Die Cutting Machines: Essential Insights for Professionals

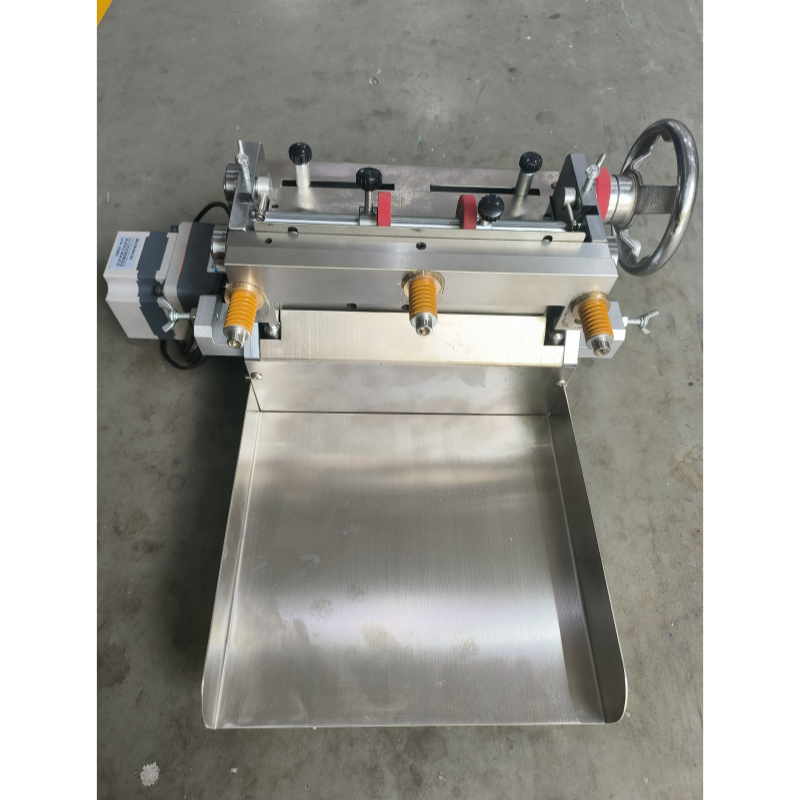

In the realm of manufacturing and post-processing machinery, the foot mat die cutting machine stands out as an essential tool for producing various types of mats and other related products. These machines are specifically designed to streamline the cutting process, ensuring precision and efficiency in the production of floor mats, rugs, and other similar items. Utilizing advanced die-cutting technology, they enable manufacturers to achieve intricate designs and accurate shapes that meet the demands of both commercial and residential applications.

At the core of the foot mat die cutting machine's functionality is its ability to handle a wide range of materials, including rubber, foam, carpet, and textiles. This versatility allows businesses to diversify their product offerings and cater to different market segments. By employing steel dies that are custom-shaped according to specific requirements, manufacturers can create unique designs that enhance the aesthetic appeal of their products while maintaining functionality.

One of the significant advantages of using a foot mat die cutting machine is the efficiency it brings to the production line. These machines are engineered to operate at high speeds, significantly reducing production time compared to manual cutting methods. This efficiency not only increases output but also minimizes material waste, leading to more cost-effective manufacturing processes. Furthermore, the precision of die cutting ensures that each product maintains consistent quality and dimensions, which is crucial for meeting customer expectations.

In addition to operational efficiency, foot mat die cutting machines are equipped with user-friendly interfaces and automation features that simplify the cutting process. Operators can easily adjust settings and monitor production, allowing for seamless integration into existing workflows. This ease of use is particularly beneficial for businesses looking to enhance productivity without compromising on quality.

Moreover, as industries continue to focus on sustainability, foot mat die cutting machines contribute to eco-friendly practices by optimizing material usage and reducing waste. Many manufacturers are now adopting sustainable materials for their mats, and the precision of die cutting helps in maximizing the use of these materials, further supporting green initiatives.

In conclusion, foot mat die cutting machines play a vital role in the manufacturing and post-processing landscape. By offering versatility, efficiency, and precision, they empower businesses to meet diverse customer demands while optimizing their production processes. Understanding the benefits and functionalities of these machines can help industry professionals make informed decisions and enhance their operational capabilities, ultimately leading to improved product offerings and customer satisfaction.

At the core of the foot mat die cutting machine's functionality is its ability to handle a wide range of materials, including rubber, foam, carpet, and textiles. This versatility allows businesses to diversify their product offerings and cater to different market segments. By employing steel dies that are custom-shaped according to specific requirements, manufacturers can create unique designs that enhance the aesthetic appeal of their products while maintaining functionality.

One of the significant advantages of using a foot mat die cutting machine is the efficiency it brings to the production line. These machines are engineered to operate at high speeds, significantly reducing production time compared to manual cutting methods. This efficiency not only increases output but also minimizes material waste, leading to more cost-effective manufacturing processes. Furthermore, the precision of die cutting ensures that each product maintains consistent quality and dimensions, which is crucial for meeting customer expectations.

In addition to operational efficiency, foot mat die cutting machines are equipped with user-friendly interfaces and automation features that simplify the cutting process. Operators can easily adjust settings and monitor production, allowing for seamless integration into existing workflows. This ease of use is particularly beneficial for businesses looking to enhance productivity without compromising on quality.

Moreover, as industries continue to focus on sustainability, foot mat die cutting machines contribute to eco-friendly practices by optimizing material usage and reducing waste. Many manufacturers are now adopting sustainable materials for their mats, and the precision of die cutting helps in maximizing the use of these materials, further supporting green initiatives.

In conclusion, foot mat die cutting machines play a vital role in the manufacturing and post-processing landscape. By offering versatility, efficiency, and precision, they empower businesses to meet diverse customer demands while optimizing their production processes. Understanding the benefits and functionalities of these machines can help industry professionals make informed decisions and enhance their operational capabilities, ultimately leading to improved product offerings and customer satisfaction.

About Us

Specializing in the production of automatic stamping equipment and punching machine peripheral equipment, is a research and development, design, production, sales, maintenance as one of the international precision stamping automation equipment manufacturing enterprises.

Contact Us

Add: Building A, Xiaoxuewei Industrial Park, Shajing, Bao'an District, Shenzhen

WhatsApp: +86 190 9240 6289

E-mail: xiaolisisale1@gmail.com

Related News