Unlocking Efficiency: How Metal Stamping Machines Transform Production

Unlocking Efficiency: How Metal Stamping Machines Transform Production

Table of Contents

- 1. Introduction to Metal Stamping

- 2. What is Metal Stamping?

- 3. Key Benefits of Metal Stamping Machines

- 4. Types of Metal Stamping Machines

- 5. Applications of Metal Stamping in Various Industries

- 6. Technological Advancements in Metal Stamping

- 7. The Future of Metal Stamping Technologies

- 8. Frequently Asked Questions

- 9. Conclusion

1. Introduction to Metal Stamping

The manufacturing landscape is continually evolving, with technology at the forefront of these changes. Among the innovations that have significantly impacted production efficiency is **metal stamping**. This process involves the use of machines designed to cut, shape, and form metal into precise components that can be utilized across various industries. In this article, we will explore how metal stamping machines enhance productivity, reduce costs, and improve product quality.

2. What is Metal Stamping?

Metal stamping is a manufacturing process that uses dies and stamping presses to transform flat metal sheets into desired shapes and forms. This technique is employed to create a plethora of products, ranging from simple components to complex assemblies. The process can involve various operations, such as blanking, punching, bending, and forming, each contributing to the overall efficiency and versatility of metal stamping.

How Metal Stamping Works

At its core, metal stamping utilizes a combination of tools and machinery to manipulate the material. The process begins with a sheet of metal placed on a die, which holds the desired shape. A stamping press then exerts immense pressure to cut or form the metal into the desired configuration. This method is highly repeatable, ensuring that each produced part maintains tight tolerances.

3. Key Benefits of Metal Stamping Machines

Metal stamping machines offer numerous advantages that enhance overall production efficiency. Let’s delve into some of the most significant benefits.

3.1 Efficiency and Speed

One of the most compelling reasons manufacturers choose **metal stamping** is its efficiency. Stamping machines are capable of producing thousands of parts per hour, significantly increasing output compared to traditional methods. This rapid production cycle allows companies to meet high demand while minimizing lead times.

3.2 Precision and Quality

Precision is crucial in manufacturing, and metal stamping machines excel in this area. With advanced controls and technology, these machines can produce components with extremely tight tolerances. This level of precision not only enhances product quality but also reduces waste, as fewer defective parts are generated.

3.3 Cost-Effectiveness

Investing in metal stamping technology can lead to substantial cost savings. The high-speed production capabilities reduce labor costs and material waste, while the durability of stamped parts often means lower costs for maintenance and replacement. Additionally, the ability to produce complex shapes in one operation further streamlines the manufacturing process.

4. Types of Metal Stamping Machines

Various types of metal stamping machines are available, each designed to achieve specific outcomes. Understanding the different types can help manufacturers choose the right equipment for their needs.

4.1 Mechanical Stamping Machines

Mechanical stamping machines utilize a flywheel system to store energy, which is then released to perform the stamping operation. These machines are known for their speed and efficiency, making them ideal for high-volume production runs. They are particularly effective for simple shapes and operations.

4.2 Hydraulic Stamping Machines

Hydraulic stamping machines operate using hydraulic cylinders to apply pressure. This allows for greater flexibility in the types of operations that can be performed. Hydraulic machines are suitable for heavier materials and complex shapes, offering greater control over the stamping process.

4.3 Servo Stamping Machines

Servo stamping machines combine the benefits of mechanical and hydraulic systems, providing precision and flexibility. The use of servo motors allows for precise adjustments during the stamping process, making them ideal for applications requiring high accuracy and speed. These machines are increasingly popular due to their energy efficiency and lower operating costs.

5. Applications of Metal Stamping in Various Industries

Metal stamping is utilized across numerous industries due to its versatility. Some common applications include:

5.1 Automotive Industry

In the automotive sector, metal stamping produces parts such as chassis, brackets, and panels. The high volume requirements in this industry make stamping a preferred method for manufacturing components efficiently and cost-effectively.

5.2 Electronics Industry

The electronics industry relies on metal stamping for components like connectors, frames, and housings. The precision of stamping ensures that parts fit together seamlessly, which is essential for electronics functionality.

5.3 Aerospace Industry

Aerospace applications demand high-quality components that meet stringent safety standards. Metal stamping provides the precision and reliability needed for parts such as brackets, fittings, and structural components.

5.4 Construction Industry

In construction, stamped metal parts are used for various applications, including structural supports and fixtures. The ability to produce durable and reliable components is vital in this industry.

6. Technological Advancements in Metal Stamping

The landscape of metal stamping is ever-evolving, thanks to advancements in technology. Innovations such as computer numerical control (CNC) technology and automation have transformed how stamping processes are executed. CNC machines enhance precision and repeatability, while automation reduces labor costs and increases production speed.

6.1 Industry 4.0 and Metal Stamping

The advent of Industry 4.0, characterized by smart manufacturing, is influencing metal stamping. With the integration of IoT (Internet of Things) technologies, manufacturers can monitor and optimize their operations in real-time. This data-driven approach leads to improved efficiency, reduced downtime, and enhanced production quality.

7. The Future of Metal Stamping Technologies

As industries continue to demand higher efficiency and quality, the future of metal stamping will likely involve further innovations. Emphasis will be placed on sustainability, with a push for eco-friendly materials and processes. Additionally, advancements in artificial intelligence (AI) and machine learning may create opportunities for more sophisticated automation and predictive maintenance techniques.

8. Frequently Asked Questions

What materials can be used in metal stamping?

Metal stamping can work with a variety of materials, including steel, aluminum, brass, copper, and various alloys. The choice of material often depends on the specific application and desired properties.

How does metal stamping compare to other manufacturing processes?

Compared to other manufacturing processes like machining or casting, metal stamping is generally faster and more cost-effective for high-volume production. It also provides superior precision and repeatability.

Can metal stamping accommodate complex designs?

Yes, modern metal stamping machines can accommodate complex designs through advanced dies and tooling. However, the complexity of the design may influence production costs and lead times.

What is the typical lead time for metal stamping projects?

Lead times for metal stamping can vary based on factors like the complexity of the design, material selection, and production volume. Generally, manufacturers can expect shorter lead times than traditional manufacturing methods.

Is metal stamping environmentally friendly?

Metal stamping can be environmentally friendly when optimized for efficiency and waste reduction. Many manufacturers are adopting sustainable practices to minimize their environmental impact, such as recycling scrap metal.

9. Conclusion

Metal stamping machines have undeniably transformed modern manufacturing by unlocking new levels of efficiency, precision, and cost-effectiveness. As industries continue to evolve, the importance of integrating advanced technologies and sustainable practices in metal stamping will only grow. By leveraging the power of these machines, manufacturers can enhance their production capabilities, meet rising demands, and stay ahead in a competitive market. Embracing the future of metal stamping is not just about keeping pace; it’s about leading the way in innovative manufacturing solutions.

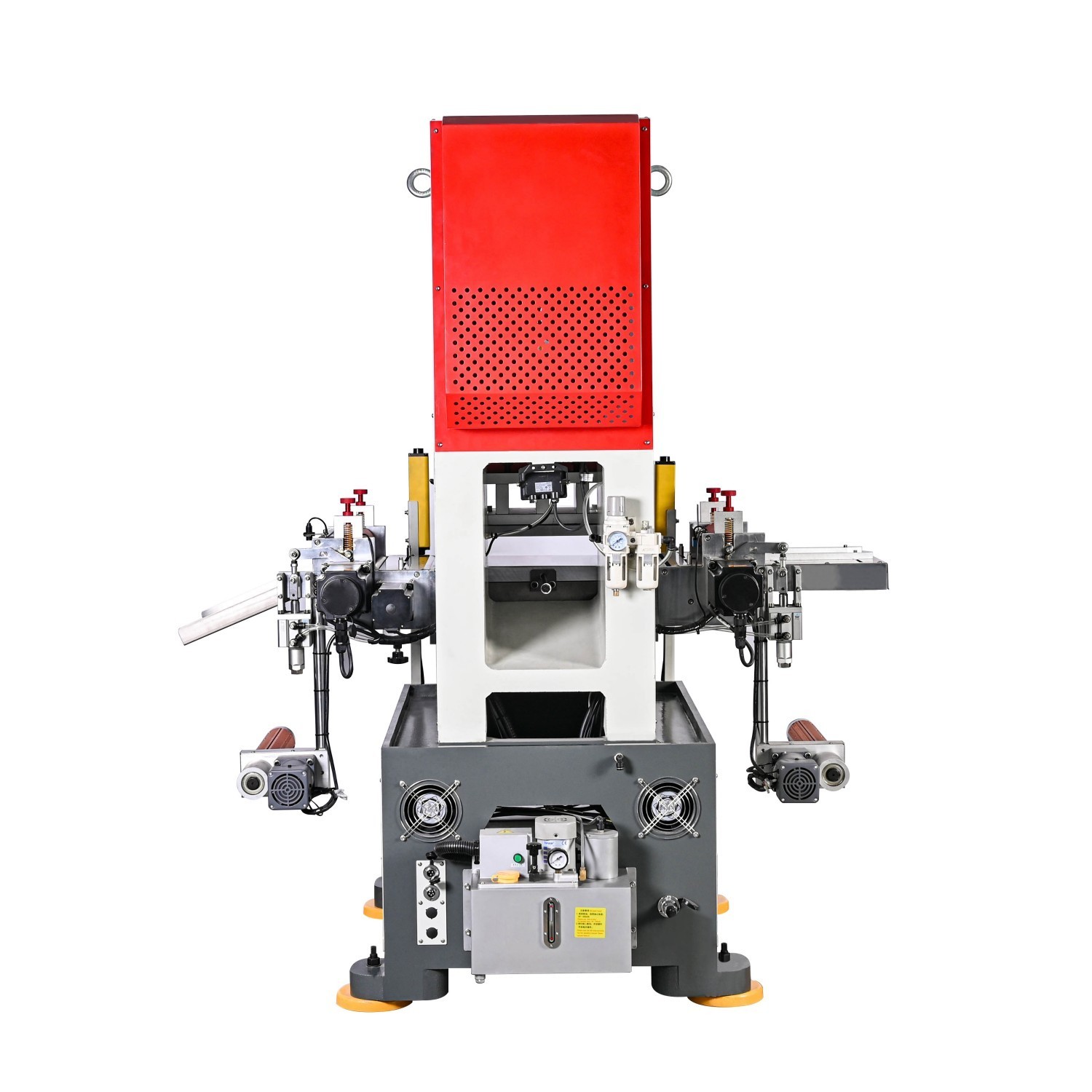

About Us

Specializing in the production of automatic stamping equipment and punching machine peripheral equipment, is a research and development, design, production, sales, maintenance as one of the international precision stamping automation equipment manufacturing enterprises.

Contact Us

Add: Building A, Xiaoxuewei Industrial Park, Shajing, Bao'an District, Shenzhen

WhatsApp: +86 190 9240 6289

E-mail: xiaolisisale1@gmail.com

Related News