Understanding the Glass Pad Die Cutting Machine: A Revolution in Post-Processing Manufacturing

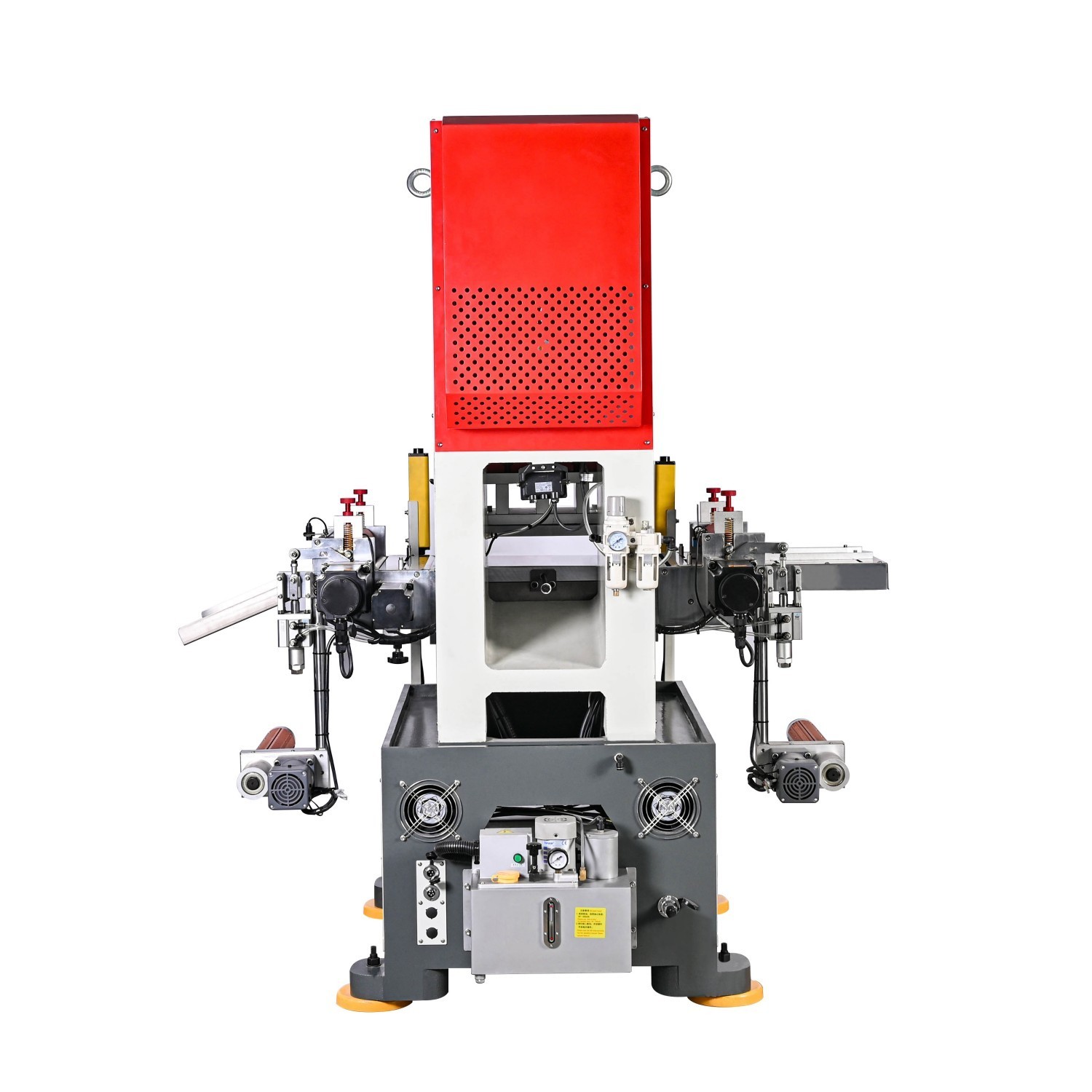

The Glass Pad Die Cutting Machine is a specialized piece of equipment designed for the precise cutting of materials in various manufacturing processes. It plays a crucial role in post-processing, a stage in manufacturing where products are finalized and prepared for delivery. This machine utilizes a glass pad, which acts as a base for the material being cut, allowing for smooth and accurate die cutting.

One of the primary advantages of using a Glass Pad Die Cutting Machine is its ability to handle a wide range of materials. From paper and cardboard to plastics and textiles, this machine can efficiently cut through diverse substances, making it ideal for industries such as packaging, automotive, textiles, and more. The versatility of the glass pad allows it to maintain flatness and stability during the cutting process, which ultimately leads to more precise and clean cuts.

In terms of operation, the Glass Pad Die Cutting Machine employs a combination of pressure and cutting dies to achieve its results. The cutting die is a specially designed tool that shapes and cuts the material into the desired form. When the upper part of the machine applies pressure, the die penetrates the material resting on the glass pad, creating the final shape. This technology ensures that the cuts are not only accurate but also repeatable, which is essential for high-volume production runs.

Another significant benefit of the Glass Pad Die Cutting Machine is its efficiency. The machine is designed to minimize waste, allowing manufacturers to maximize their raw materials. As a result, businesses can save on costs while also contributing to more sustainable production practices. Additionally, the speed of the die-cutting process can significantly reduce turnaround times, making it an excellent choice for companies that require quick delivery of products.

Moreover, this type of die-cutting technology allows for intricate designs and shapes, which are often essential in creating appealing packaging and branding materials. With the capability to produce precise cuts, manufacturers can create unique and complex designs that stand out in the market.

In conclusion, the Glass Pad Die Cutting Machine represents a significant advancement in the field of post-processing manufacturing. Its ability to handle various materials, deliver precise cuts, and enhance production efficiency makes it an invaluable tool for manufacturers looking to improve their processes. As industries continue to evolve, investing in such innovative machinery can lead to better product quality and competitive advantages in the marketplace. By understanding the benefits and capabilities of the Glass Pad Die Cutting Machine, manufacturers can make informed decisions that align with their production needs and goals.

One of the primary advantages of using a Glass Pad Die Cutting Machine is its ability to handle a wide range of materials. From paper and cardboard to plastics and textiles, this machine can efficiently cut through diverse substances, making it ideal for industries such as packaging, automotive, textiles, and more. The versatility of the glass pad allows it to maintain flatness and stability during the cutting process, which ultimately leads to more precise and clean cuts.

In terms of operation, the Glass Pad Die Cutting Machine employs a combination of pressure and cutting dies to achieve its results. The cutting die is a specially designed tool that shapes and cuts the material into the desired form. When the upper part of the machine applies pressure, the die penetrates the material resting on the glass pad, creating the final shape. This technology ensures that the cuts are not only accurate but also repeatable, which is essential for high-volume production runs.

Another significant benefit of the Glass Pad Die Cutting Machine is its efficiency. The machine is designed to minimize waste, allowing manufacturers to maximize their raw materials. As a result, businesses can save on costs while also contributing to more sustainable production practices. Additionally, the speed of the die-cutting process can significantly reduce turnaround times, making it an excellent choice for companies that require quick delivery of products.

Moreover, this type of die-cutting technology allows for intricate designs and shapes, which are often essential in creating appealing packaging and branding materials. With the capability to produce precise cuts, manufacturers can create unique and complex designs that stand out in the market.

In conclusion, the Glass Pad Die Cutting Machine represents a significant advancement in the field of post-processing manufacturing. Its ability to handle various materials, deliver precise cuts, and enhance production efficiency makes it an invaluable tool for manufacturers looking to improve their processes. As industries continue to evolve, investing in such innovative machinery can lead to better product quality and competitive advantages in the marketplace. By understanding the benefits and capabilities of the Glass Pad Die Cutting Machine, manufacturers can make informed decisions that align with their production needs and goals.

About Us

Specializing in the production of automatic stamping equipment and punching machine peripheral equipment, is a research and development, design, production, sales, maintenance as one of the international precision stamping automation equipment manufacturing enterprises.

Contact Us

Add: Building A, Xiaoxuewei Industrial Park, Shajing, Bao'an District, Shenzhen

WhatsApp: +86 190 9240 6289

E-mail: xiaolisisale1@gmail.com

Related News