Understanding Small Metal Stamping Machines: A Comprehensive Guide

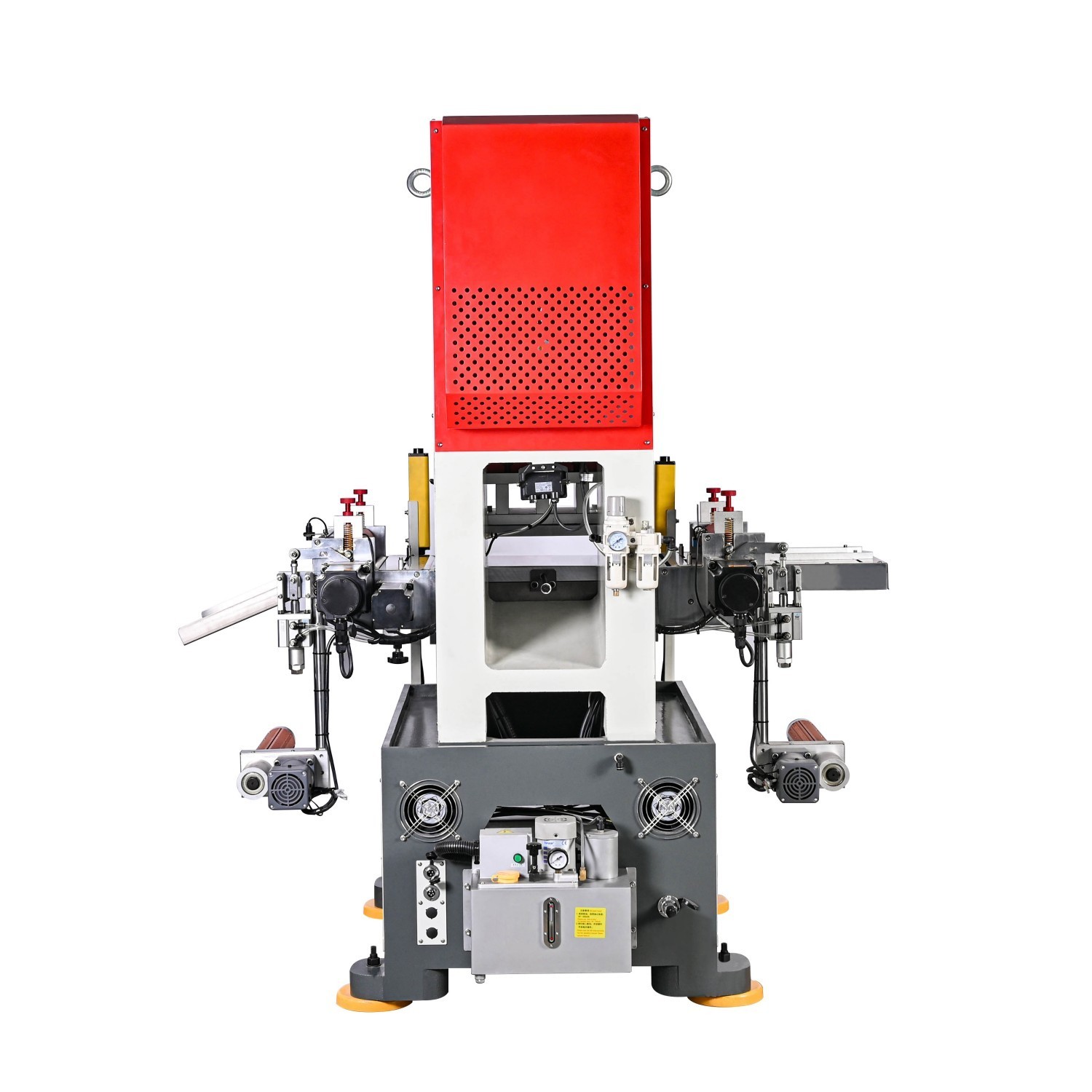

Small metal stamping machines are pivotal in the manufacturing and processing of various metal components. These machines are designed to create intricate shapes and designs from metal sheets through a process known as stamping. The process typically involves the use of dies, which are specialized tools that shape the metal as it is pressed. Understanding the functionality and benefits of small metal stamping machines can help manufacturers optimize their production processes.

One of the primary advantages of small metal stamping machines is their efficiency. These machines can operate at high speeds, significantly increasing production rates compared to manual processes. By automating the stamping process, manufacturers can reduce labor costs and minimize the risk of human error. This efficiency is particularly beneficial for producing high volumes of parts consistently and accurately.

Another critical aspect of small metal stamping machines is their versatility. They are capable of working with various materials, including aluminum, brass, copper, and stainless steel. This flexibility allows manufacturers to create a wide range of products, from simple brackets and clips to more complex components used in automotive and electronic applications. The adaptability of small metal stamping machines also facilitates customization, enabling manufacturers to meet specific design requirements and client needs.

Moreover, the precision offered by small metal stamping machines is noteworthy. With advanced technology, these machines can achieve tight tolerances and intricate designs, which are essential for parts that require a high degree of accuracy. The precision stamping process also contributes to improved product quality, reducing the need for secondary operations and minimizing waste.

In terms of maintenance and operation, small metal stamping machines are relatively straightforward. Regular maintenance ensures optimal performance and longevity, allowing manufacturers to maximize their investment. Additionally, training for operators is generally less intensive than for more complex machinery, making it easier to incorporate new staff into the production process.

Finally, as industries continue to innovate and evolve, the role of small metal stamping machines will likely expand. With advancements in technology, such as the integration of smart manufacturing practices and automation, these machines are becoming even more essential in meeting the demands of modern production.

In summary, small metal stamping machines play a critical role in the manufacturing sector by offering efficiency, versatility, precision, and ease of operation. As businesses strive to enhance productivity and quality, understanding the capabilities of these machines will be vital for staying competitive in the fast-paced manufacturing landscape.

One of the primary advantages of small metal stamping machines is their efficiency. These machines can operate at high speeds, significantly increasing production rates compared to manual processes. By automating the stamping process, manufacturers can reduce labor costs and minimize the risk of human error. This efficiency is particularly beneficial for producing high volumes of parts consistently and accurately.

Another critical aspect of small metal stamping machines is their versatility. They are capable of working with various materials, including aluminum, brass, copper, and stainless steel. This flexibility allows manufacturers to create a wide range of products, from simple brackets and clips to more complex components used in automotive and electronic applications. The adaptability of small metal stamping machines also facilitates customization, enabling manufacturers to meet specific design requirements and client needs.

Moreover, the precision offered by small metal stamping machines is noteworthy. With advanced technology, these machines can achieve tight tolerances and intricate designs, which are essential for parts that require a high degree of accuracy. The precision stamping process also contributes to improved product quality, reducing the need for secondary operations and minimizing waste.

In terms of maintenance and operation, small metal stamping machines are relatively straightforward. Regular maintenance ensures optimal performance and longevity, allowing manufacturers to maximize their investment. Additionally, training for operators is generally less intensive than for more complex machinery, making it easier to incorporate new staff into the production process.

Finally, as industries continue to innovate and evolve, the role of small metal stamping machines will likely expand. With advancements in technology, such as the integration of smart manufacturing practices and automation, these machines are becoming even more essential in meeting the demands of modern production.

In summary, small metal stamping machines play a critical role in the manufacturing sector by offering efficiency, versatility, precision, and ease of operation. As businesses strive to enhance productivity and quality, understanding the capabilities of these machines will be vital for staying competitive in the fast-paced manufacturing landscape.

About Us

Specializing in the production of automatic stamping equipment and punching machine peripheral equipment, is a research and development, design, production, sales, maintenance as one of the international precision stamping automation equipment manufacturing enterprises.

Contact Us

Add: Building A, Xiaoxuewei Industrial Park, Shajing, Bao'an District, Shenzhen

WhatsApp: +86 190 9240 6289

E-mail: xiaolisisale1@gmail.com

Related News