Exploring the Benefits and Applications of Shielding Die Cutting Machines

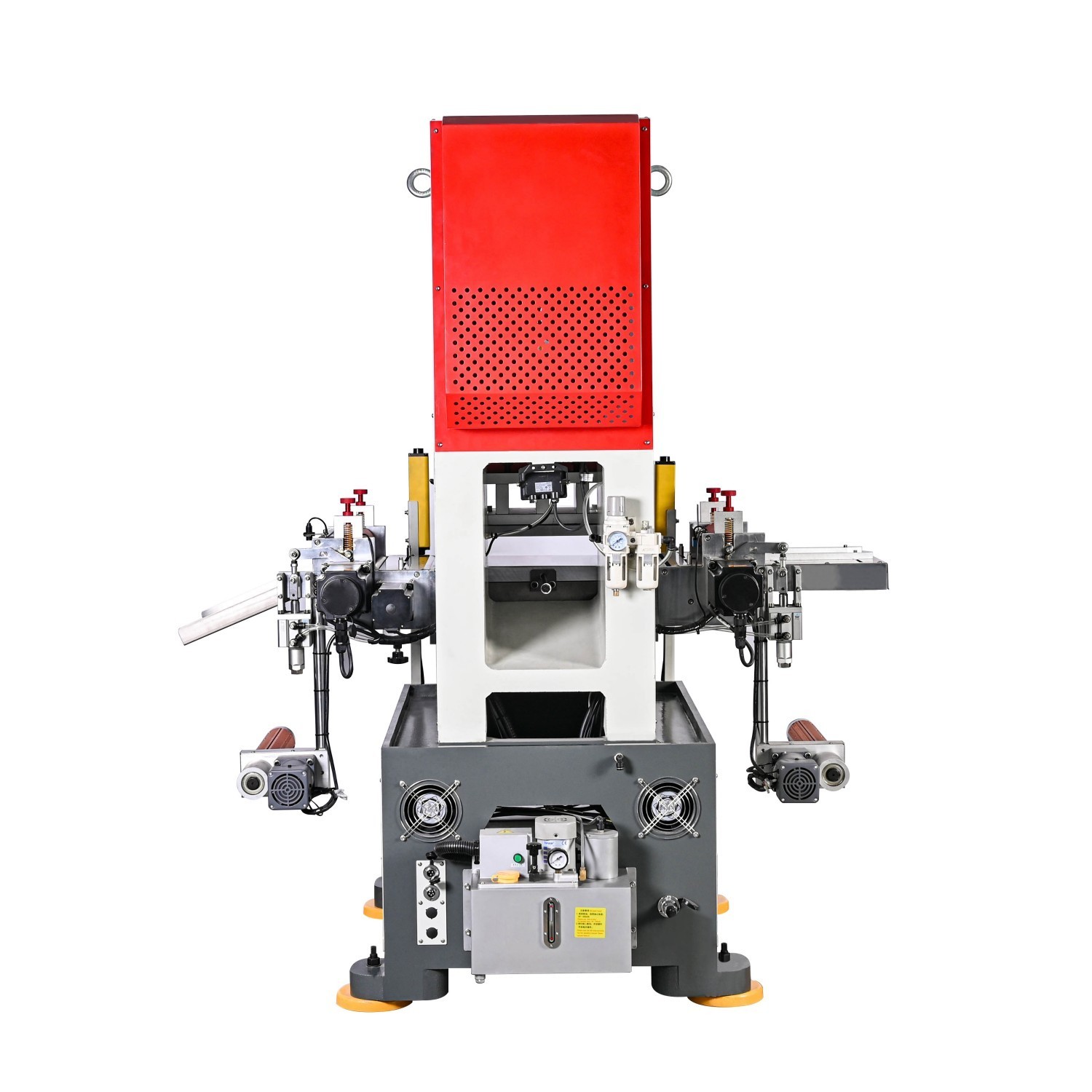

Shielding Die Cutting Machines play a vital role in the manufacturing and processing of materials, particularly in post-printing operations. These machines are designed to create precise cuts in various substrates, including paper, cardboard, plastic, and metal, making them an essential tool in several industries. Understanding the advantages and applications of Shielding Die Cutting Machines can help businesses optimize their workflow and improve product quality.

One of the primary benefits of Shielding Die Cutting Machines is their ability to produce intricate and complex shapes with high accuracy. The precision cutting capabilities enable manufacturers to create detailed designs that would be difficult or impossible to achieve with traditional cutting methods. This accuracy not only enhances the aesthetic appeal of the final product but also ensures that components fit together seamlessly, which is particularly important in industries such as packaging and electronics.

Another significant advantage of these machines is their efficiency. Shielding Die Cutting Machines can operate at high speeds, allowing for rapid production cycles. This efficiency is crucial in a competitive market, where time is often of the essence. By reducing the time required for cutting operations, businesses can increase their output and meet customer demands more effectively.

Moreover, the versatility of Shielding Die Cutting Machines makes them suitable for a wide range of applications. They can be utilized in manufacturing various products, such as labels, stickers, packaging materials, and automotive components. This multi-functionality allows businesses to streamline their processes and reduce the need for multiple machines. Companies can invest in a single Shielding Die Cutting Machine and use it for various tasks, which can lead to cost savings and simplified operations.

In addition to precision and efficiency, Shielding Die Cutting Machines also contribute to waste reduction. Traditional cutting methods often generate a significant amount of scrap material. However, with advanced die cutting technology, manufacturers can optimize material usage, minimizing waste and thus reducing environmental impact. This eco-friendly approach not only helps in cost management but also aligns with the growing demand for sustainable practices within the industry.

Furthermore, integrating Shielding Die Cutting Machines with modern technology, such as computer numerical control (CNC) and automation, enhances their capabilities. These advanced features allow for programmable settings that can be adjusted for different materials and designs, further improving productivity and consistency.

In conclusion, Shielding Die Cutting Machines represent a significant advancement in the manufacturing and processing sector, offering precision, efficiency, versatility, and waste reduction. As industries continue to evolve, embracing these cutting-edge technologies will be essential for businesses seeking to maintain a competitive edge and meet the ever-changing demands of the market. By understanding the advantages and applications of Shielding Die Cutting Machines, manufacturers can make informed decisions that enhance their production capabilities and drive success.

One of the primary benefits of Shielding Die Cutting Machines is their ability to produce intricate and complex shapes with high accuracy. The precision cutting capabilities enable manufacturers to create detailed designs that would be difficult or impossible to achieve with traditional cutting methods. This accuracy not only enhances the aesthetic appeal of the final product but also ensures that components fit together seamlessly, which is particularly important in industries such as packaging and electronics.

Another significant advantage of these machines is their efficiency. Shielding Die Cutting Machines can operate at high speeds, allowing for rapid production cycles. This efficiency is crucial in a competitive market, where time is often of the essence. By reducing the time required for cutting operations, businesses can increase their output and meet customer demands more effectively.

Moreover, the versatility of Shielding Die Cutting Machines makes them suitable for a wide range of applications. They can be utilized in manufacturing various products, such as labels, stickers, packaging materials, and automotive components. This multi-functionality allows businesses to streamline their processes and reduce the need for multiple machines. Companies can invest in a single Shielding Die Cutting Machine and use it for various tasks, which can lead to cost savings and simplified operations.

In addition to precision and efficiency, Shielding Die Cutting Machines also contribute to waste reduction. Traditional cutting methods often generate a significant amount of scrap material. However, with advanced die cutting technology, manufacturers can optimize material usage, minimizing waste and thus reducing environmental impact. This eco-friendly approach not only helps in cost management but also aligns with the growing demand for sustainable practices within the industry.

Furthermore, integrating Shielding Die Cutting Machines with modern technology, such as computer numerical control (CNC) and automation, enhances their capabilities. These advanced features allow for programmable settings that can be adjusted for different materials and designs, further improving productivity and consistency.

In conclusion, Shielding Die Cutting Machines represent a significant advancement in the manufacturing and processing sector, offering precision, efficiency, versatility, and waste reduction. As industries continue to evolve, embracing these cutting-edge technologies will be essential for businesses seeking to maintain a competitive edge and meet the ever-changing demands of the market. By understanding the advantages and applications of Shielding Die Cutting Machines, manufacturers can make informed decisions that enhance their production capabilities and drive success.

About Us

Specializing in the production of automatic stamping equipment and punching machine peripheral equipment, is a research and development, design, production, sales, maintenance as one of the international precision stamping automation equipment manufacturing enterprises.

Contact Us

Add: Building A, Xiaoxuewei Industrial Park, Shajing, Bao'an District, Shenzhen

WhatsApp: +86 190 9240 6289

E-mail: xiaolisisale1@gmail.com

Related News