Precision Die Cutting Machines: Enhancing Product Quality and Consistency

Precision Die Cutting Machines: Enhancing Product Quality and Consistency

Table of Contents

- 1. Introduction to Precision Die Cutting Machines

- 2. The Importance of Quality and Consistency in Manufacturing

- 3. Key Features of Modern Die Cutting Machines

- 4. Types of Precision Die Cutting Machines

- 5. Benefits of Using Precision Die Cutting Machines

- 6. Applications in Various Industries

- 7. How to Choose the Right Die Cutting Machine

- 8. The Future of Die Cutting Technology

- 9. Frequently Asked Questions

- 10. Conclusion

1. Introduction to Precision Die Cutting Machines

Precision die cutting machines play a crucial role in the manufacturing sector, particularly in industries that require exact specifications and high-quality outputs. These machines are designed to cut a variety of materials, including paper, plastic, metal, and textiles, with precision and efficiency. With an increasing demand for custom-shaped products, precision die cutting technology has evolved to meet the challenges of modern manufacturing.

2. The Importance of Quality and Consistency in Manufacturing

Quality and consistency are paramount in any manufacturing process. Products that are well-made not only enhance a brand's reputation but also meet customer expectations, leading to increased satisfaction and loyalty. Precision die cutting machines ensure that each cut is uniform, reducing material waste and lowering production costs. This consistency is vital for industries such as packaging, automotive, and electronics, where deviations can result in significant financial losses.

3. Key Features of Modern Die Cutting Machines

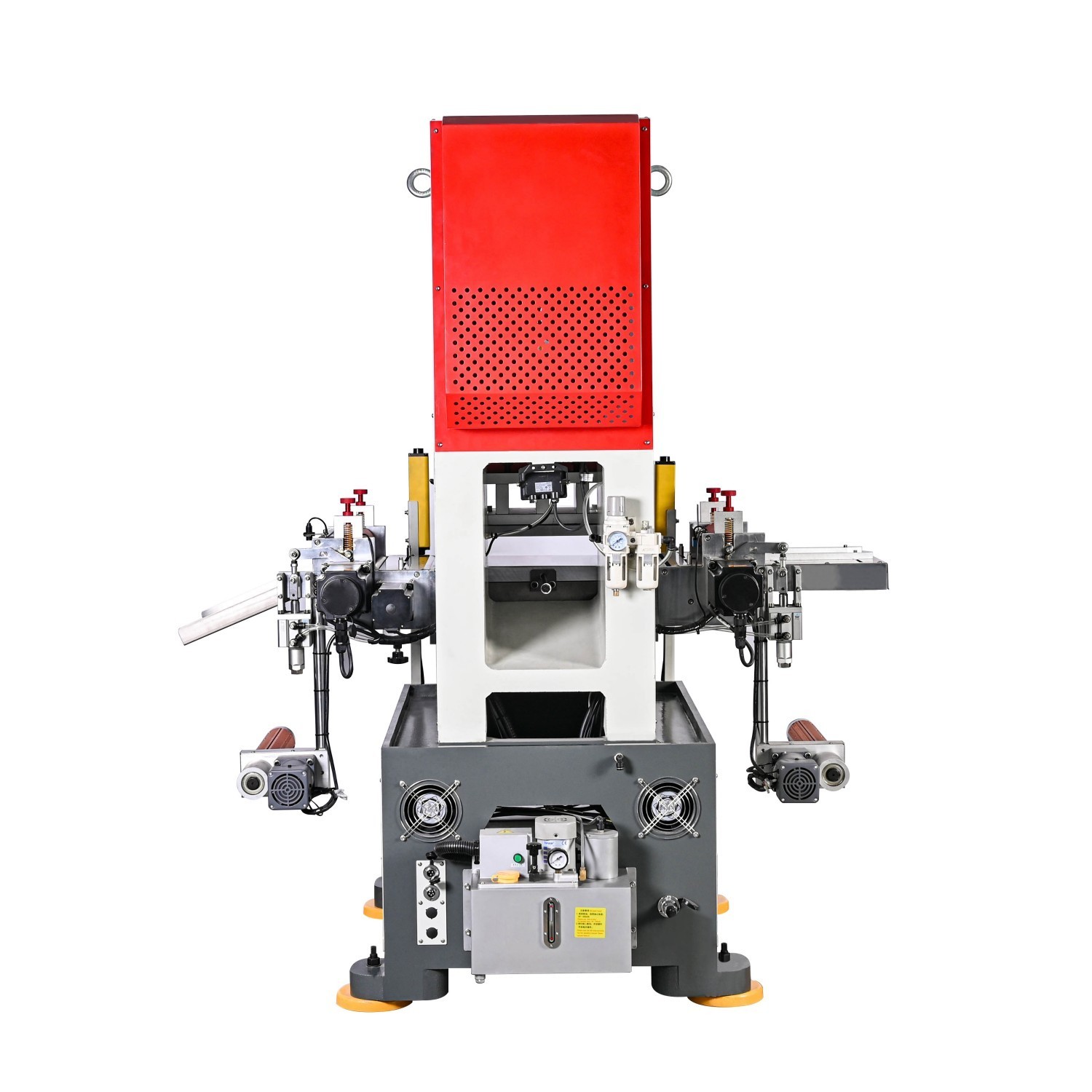

Today's precision die cutting machines come equipped with a range of advanced features, including:

- **Automatic Material Feeding**: This feature minimizes manual labor and increases efficiency.

- **Digital Controls**: Digital interfaces allow for easy adjustments and monitoring of the cutting process, ensuring precision.

- **Customizable Die Sets**: Manufacturers can create specific die sets tailored to their production needs, providing flexibility.

- **Safety Mechanisms**: Modern machines include various safety features to protect operators during the cutting process.

- **Speed and Efficiency**: With enhanced speed capabilities, these machines can process large volumes of products quickly, maintaining high productivity levels.

4. Types of Precision Die Cutting Machines

There are several types of precision die cutting machines available, each designed for specific applications. Understanding the differences among them can help manufacturers select the right machine for their needs.

4.1 Rotary Die Cutting Machines

Rotary die cutting machines use a cylindrical die to cut materials as they pass through the machine. This method is especially effective for large-scale production runs, where speed and efficiency are critical. Rotary die cutting is often used in packaging and labeling applications.

4.2 Flatbed Die Cutting Machines

Flatbed die cutting machines utilize a flat die that presses down on the material. This type is suitable for smaller production runs and intricate designs, providing high-quality cuts with excellent detail. Flatbed machines are commonly used in industries such as textiles and graphics.

4.3 Laser Die Cutting Machines

Laser die cutting machines use focused laser beams to cut materials with extreme precision. This technology allows for complex shapes and intricate designs that traditional methods may struggle to achieve. Laser cutting is ideal for industries requiring high levels of customization, such as fashion and electronics.

5. Benefits of Using Precision Die Cutting Machines

Incorporating precision die cutting machines into your manufacturing process offers numerous advantages:

- **Enhanced Product Quality**: Consistent cuts ensure that products meet stringent quality standards.

- **Increased Efficiency**: Automated processes reduce manual intervention, speeding up production.

- **Cost-Effectiveness**: Lower material waste and higher output can lead to significant cost savings.

- **Versatility**: These machines can handle various materials, making them suitable for diverse applications.

- **Customization**: The ability to create custom die sets allows for tailored production solutions.

6. Applications in Various Industries

Precision die cutting machines find applications across multiple industries, enhancing productivity and quality. Some prominent sectors include:

- **Packaging**: Creating boxes, labels, and other packaging materials with precision.

- **Textiles**: Cutting fabrics for garments and other textile products.

- **Electronics**: Manufacturing components that require precise shapes and sizes.

- **Automotive**: Producing parts with exact specifications for optimal performance.

- **Printing**: Crafting printed materials into custom shapes and sizes.

7. How to Choose the Right Die Cutting Machine

Selecting the appropriate precision die cutting machine requires careful consideration of several factors:

- **Material Types**: Determine which materials you will be cutting and choose a machine that can handle them effectively.

- **Production Volume**: Consider the scale of your production needs, as some machines are better suited for high-volume runs.

- **Complexity of Cuts**: Assess the intricacy of the designs you intend to produce; some machines excel at complex shapes.

- **Budget**: Establish a budget that aligns with your production goals while considering long-term operational costs.

- **Technical Support**: Evaluate the manufacturer's support and service options to ensure you have assistance when needed.

8. The Future of Die Cutting Technology

As technology advances, the future of precision die cutting will likely incorporate innovations such as artificial intelligence and automation. These developments can further enhance efficiency, reduce waste, and improve overall product quality. With the rising trend of sustainable manufacturing, machines that minimize environmental impact while maintaining high standards will become increasingly popular.

9. Frequently Asked Questions

1. What materials can be cut with precision die cutting machines?

Precision die cutting machines can cut a wide range of materials, including paper, cardboard, plastics, metals, and textiles.

2. How do I determine the right type of die cutting machine for my needs?

Consider factors such as the material types, production volume, complexity of cuts, budget, and required features when selecting a machine.

3. Are precision die cutting machines suitable for small businesses?

Yes, there are various models available that cater to small businesses, offering cost-effective solutions for lower production volumes.

4. How can precision die cutting improve product quality?

By providing consistent and accurate cuts, these machines minimize defects and ensure that products meet quality standards.

5. What is the typical lifespan of a precision die cutting machine?

With proper maintenance, precision die cutting machines can last many years, although the lifespan may vary based on usage and model.

10. Conclusion

Precision die cutting machines are indispensable tools that significantly enhance product quality and consistency across various industries. By understanding the key features, types, and benefits of these machines, manufacturers can make informed decisions that improve their production processes. As technology continues to evolve, investing in precision die cutting machines will ensure that businesses remain competitive in an ever-changing market.

About Us

Specializing in the production of automatic stamping equipment and punching machine peripheral equipment, is a research and development, design, production, sales, maintenance as one of the international precision stamping automation equipment manufacturing enterprises.

Contact Us

Add: Building A, Xiaoxuewei Industrial Park, Shajing, Bao'an District, Shenzhen

WhatsApp: +86 190 9240 6289

E-mail: xiaolisisale1@gmail.com

Related News