Unlocking the Potential: How Cotton Paper Die Cutting Machines Transform Manufacturing

Unlocking the Potential: How Cotton Paper Die Cutting Machines Transform Manufacturing

Table of Contents

1. Introduction to Cotton Paper Die Cutting Machines

2. The Importance of Die Cutting in Manufacturing

3. Key Features of Cotton Paper Die Cutting Machines

3.1 Precision Engineering for Optimal Results

3.2 Versatility in Materials Handling

3.3 Automation and Efficiency

4. Benefits of Using Cotton Paper Die Cutting Machines

4.1 Enhanced Production Efficiency

4.2 Cost-Effectiveness and Resource Management

4.3 Eco-Friendly Manufacturing Practices

5. Applications of Cotton Paper Die Cutting Machines

5.1 Packaging Industry Innovations

5.2 Creative Arts and Crafts Revolution

5.3 Commercial Printing Advancements

6. How to Choose the Right Die Cutting Machine

6.1 Assessing Your Manufacturing Needs

6.2 Comparing Different Machine Models

7. Maintenance Tips for Cotton Paper Die Cutting Machines

8. Future Trends in Die Cutting Technology

9. Frequently Asked Questions (FAQs)

10. Conclusion

1. Introduction to Cotton Paper Die Cutting Machines

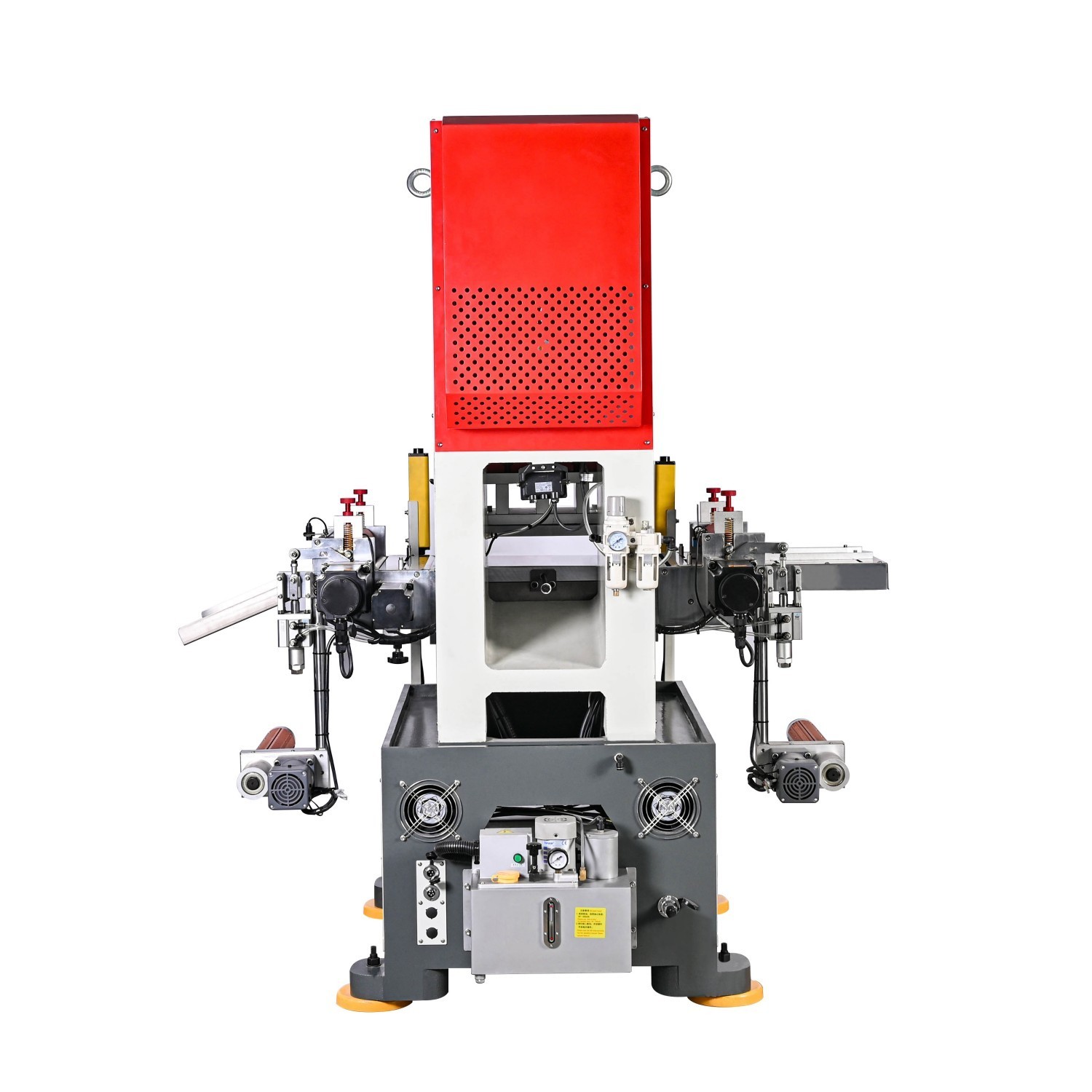

In the ever-evolving landscape of manufacturing, **cotton paper die cutting machines** have emerged as vital tools for enhancing production capabilities. These machines are engineered to cut precise shapes and designs from cotton paper, a material cherished for its durability and eco-friendliness. As industries recognize the potential of these machines, the demand continues to grow, leading to innovation in **manufacturing processes**.

2. The Importance of Die Cutting in Manufacturing

Die cutting is a crucial procedure in various manufacturing sectors, allowing for the creation of intricate shapes and designs with precision. This technique not only improves the aesthetic appeal of products but also optimizes material usage, thus reducing waste. With the rise of custom-designed products, die cutting has become indispensable in meeting consumer expectations while streamlining production workflows.

3. Key Features of Cotton Paper Die Cutting Machines

Understanding the features of cotton paper die cutting machines is essential for optimizing their use in manufacturing. Here are some distinguishing characteristics:

3.1 Precision Engineering for Optimal Results

One of the standout features of these machines is their precision engineering. They are designed to ensure that every cut is exact, minimizing errors and improving the quality of the final product. This precision is critical in industries where detail matters, such as packaging and product design.

3.2 Versatility in Materials Handling

Cotton paper die cutting machines are incredibly versatile. They can handle various thicknesses and types of cotton paper, allowing manufacturers to experiment with different materials to achieve desired results. This versatility enables businesses to diversify their product offerings and cater to various market needs.

3.3 Automation and Efficiency

Modern die cutting machines often come equipped with advanced automation features. These innovations not only speed up production but also reduce the likelihood of human error. Automated settings allow for quick adjustments and reprogramming, making it easier to switch between different projects without losing efficiency.

4. Benefits of Using Cotton Paper Die Cutting Machines

The adoption of cotton paper die cutting machines brings numerous benefits to manufacturers:

4.1 Enhanced Production Efficiency

With their ability to produce consistent cuts quickly, these machines significantly enhance overall production efficiency. Manufacturers can meet tight deadlines and adapt to market demands more effectively, ensuring they stay competitive.

4.2 Cost-Effectiveness and Resource Management

Investing in a cotton paper die cutting machine can lead to substantial cost savings. By reducing material wastage and improving operational efficiency, manufacturers can lower their production costs. Additionally, the long lifespan of these machines contributes to their cost-effectiveness over time.

4.3 Eco-Friendly Manufacturing Practices

Sustainability is more critical than ever in today's manufacturing landscape. Cotton paper die cutting machines promote eco-friendly practices by allowing for the use of biodegradable materials and minimizing waste. This aligns with the growing consumer demand for sustainable products, enhancing brand reputation and marketability.

5. Applications of Cotton Paper Die Cutting Machines

The versatility of cotton paper die cutting machines opens up a myriad of applications across various industries:

5.1 Packaging Industry Innovations

The packaging industry has greatly benefited from the precision and efficiency of cotton paper die cutting machines. These machines produce custom packaging solutions that are not only functional but also visually appealing, attracting consumers and enhancing brand identity.

5.2 Creative Arts and Crafts Revolution

Artists and crafters leverage cotton paper die cutting machines to create intricate designs for scrapbooking, card making, and other crafts. These machines enable creativity without the limitations of manual cutting, inspiring new artistic expressions and projects.

5.3 Commercial Printing Advancements

In commercial printing, die cutting enhances the production of unique marketing materials, such as brochures, business cards, and promotional items. The ability to create custom shapes allows businesses to stand out in crowded markets, making a lasting impression on customers.

6. How to Choose the Right Die Cutting Machine

Selecting the right cotton paper die cutting machine for your manufacturing needs requires careful consideration of several factors:

6.1 Assessing Your Manufacturing Needs

Before investing in a die cutting machine, it's essential to evaluate your production requirements. Consider the volume of production, types of products, and desired level of customization. This assessment will help narrow down machine options that align with your operational goals.

6.2 Comparing Different Machine Models

Research various cotton paper die cutting machine models, focusing on features, price, and customer reviews. Look for machines that offer a balance between quality, functionality, and affordability. Consulting with industry experts can also provide valuable insights into the best options available.

7. Maintenance Tips for Cotton Paper Die Cutting Machines

To ensure longevity and optimal performance, regular maintenance of cotton paper die cutting machines is crucial. Here are some essential maintenance tips:

1. **Regular Cleaning:** Remove dust and debris from the machine after each use to prevent buildup that could affect performance.

2. **Inspect Blades:** Regularly check the condition of cutting blades and replace them as needed to ensure clean cuts.

3. **Lubrication:** Follow the manufacturer’s guidelines on lubrication to keep moving parts functioning smoothly.

4. **Calibration:** Periodically calibrate the machine to maintain accuracy in cutting dimensions.

8. Future Trends in Die Cutting Technology

As technology continues to evolve, die cutting machines are expected to become even more advanced. Future trends may include enhanced automation features, integration with digital design tools, and improved energy efficiency. Staying ahead of these trends will be vital for manufacturers looking to maintain a competitive edge.

9. Frequently Asked Questions (FAQs)

What is a cotton paper die cutting machine?

A cotton paper die cutting machine is a specialized piece of equipment used to cut intricate shapes from cotton paper with precision and efficiency.

How does die cutting improve manufacturing processes?

Die cutting enhances manufacturing by increasing production efficiency, reducing material waste, and allowing for the creation of customized products.

What industries benefit the most from cotton paper die cutting machines?

Industries such as packaging, commercial printing, and arts and crafts benefit significantly from the precision and versatility of these machines.

How do I maintain my cotton paper die cutting machine?

Regular maintenance includes cleaning, inspecting and replacing blades, lubricating moving parts, and calibrating the machine as needed.

What should I consider when purchasing a die cutting machine?

When purchasing a die cutting machine, consider your production needs, the machine’s features, customer reviews, and overall cost-effectiveness.

10. Conclusion

Cotton paper die cutting machines are transforming the landscape of manufacturing by delivering precision, efficiency, and sustainability. Their versatility across applications—from packaging to creative arts—makes them invaluable assets for businesses aiming to innovate and excel. As the industry continues to evolve, embracing these advanced machines is essential for maintaining a competitive edge and meeting the growing consumer demand for customized, eco-friendly products. Investing in a cotton paper die cutting machine not only enhances production capabilities but also aligns with the future of sustainable manufacturing practices.

About Us

Specializing in the production of automatic stamping equipment and punching machine peripheral equipment, is a research and development, design, production, sales, maintenance as one of the international precision stamping automation equipment manufacturing enterprises.

Contact Us

Add: Building A, Xiaoxuewei Industrial Park, Shajing, Bao'an District, Shenzhen

WhatsApp: +86 190 9240 6289

E-mail: xiaolisisale1@gmail.com

Related News