Maximizing Efficiency: The Benefits of Using a Foot Mat Die Cutting Machine

Maximizing Efficiency: The Benefits of Using a Foot Mat Die Cutting Machine

Introduction to Foot Mat Die Cutting Machines

In the fast-paced world of manufacturing, efficiency and precision are of utmost importance. **Foot mat die cutting machines** have emerged as indispensable tools in the production of mats for various applications, from automotive floor mats to industrial safety products. These machines offer significant advantages that can maximize productivity while minimizing material waste.

In this article, we will delve deep into the benefits of using a foot mat die cutting machine and explore how this technology can transform your manufacturing process.

Understanding Die Cutting Technology

What is Die Cutting?

Die cutting is a process that involves the use of a die to cut materials into specific shapes and sizes. This process is widely used in various industries, including textiles, rubber, and plastics. The die cutting machine applies pressure to the material, allowing it to be cut precisely, ensuring high-quality output.

The Role of Foot Mat Die Cutting Machines

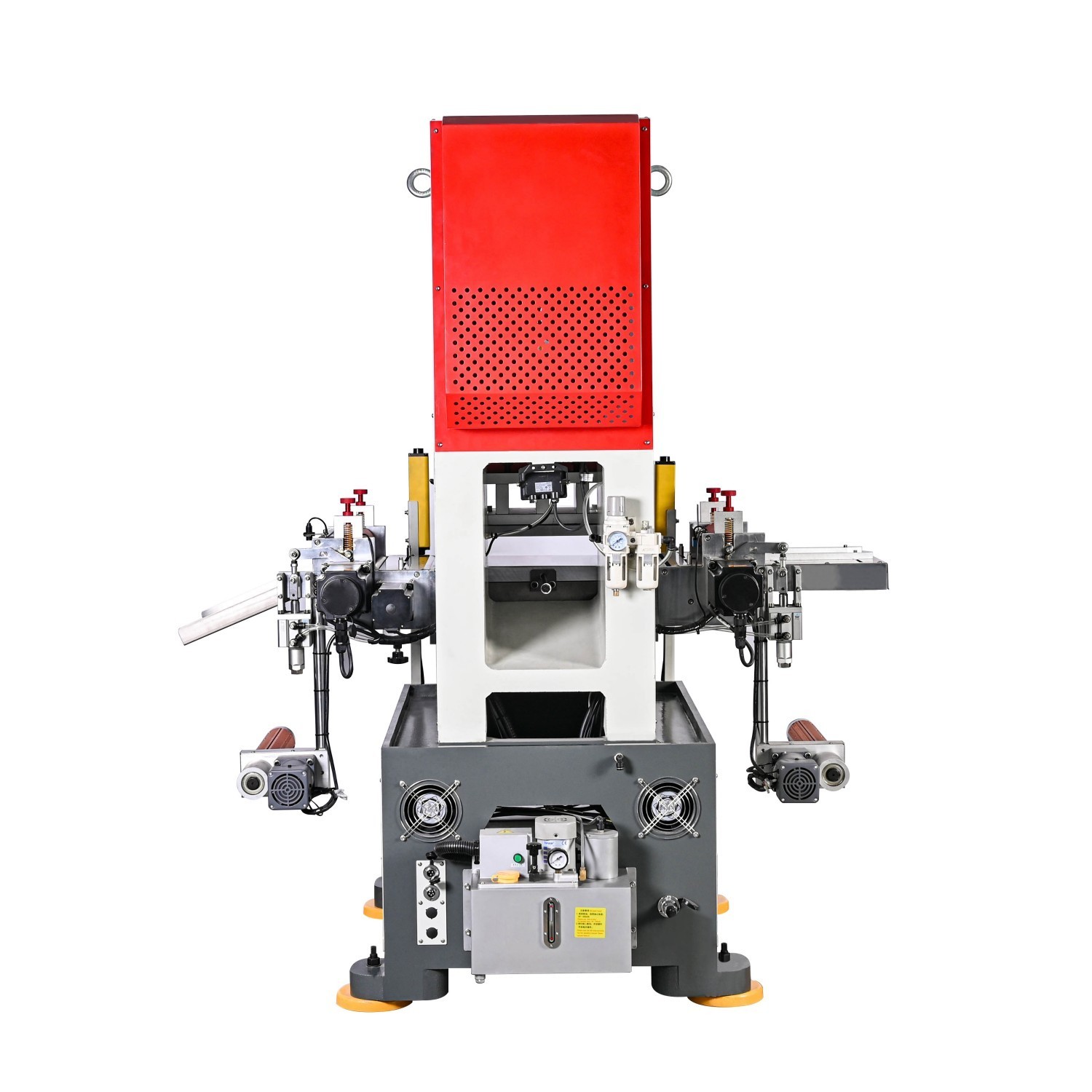

Foot mat die cutting machines are specifically designed for cutting mat materials such as rubber, foam, and carpet. These machines utilize advanced technology to enhance precision and efficiency during the production process.

Key Advantages of Foot Mat Die Cutting Machines

1. Enhanced Production Speed

One of the primary benefits of using a foot mat die cutting machine is the significant increase in production speed. Traditional cutting methods can be time-consuming and labor-intensive. In contrast, die cutting machines operate at a much faster rate, allowing businesses to meet high-volume demands without compromising quality.

Automated Processes for Increased Throughput

Many foot mat die cutting machines come equipped with automated features that streamline the entire cutting process. These include automated feeding systems and programmable controls that allow for quick adjustments and set-ups, further enhancing productivity.

2. Precision and Consistency

Precision is critical in manufacturing, and foot mat die cutting machines excel in delivering consistent results. The use of precise dies ensures that each piece cut is uniform in size and shape, thereby reducing the likelihood of errors and rework.

Quality Control through Automation

By integrating automated quality control measures, manufacturers can monitor production in real time, ensuring that every mat meets the required specifications. This level of precision not only improves product quality but also enhances customer satisfaction.

3. Cost-Effectiveness

Investing in a foot mat die cutting machine can lead to significant cost savings over time. Although the initial investment may be higher than traditional cutting methods, the long-term benefits far outweigh the costs.

Reduction of Material Waste

Die cutting machines are designed to minimize material waste. By utilizing advanced cutting techniques and efficient layouts, manufacturers can maximize the use of raw materials, ultimately leading to reduced expenses.

4. Versatility in Material Handling

Foot mat die cutting machines are capable of handling a wide variety of materials, which makes them incredibly versatile. Whether you are working with rubber, foam, or composite materials, these machines can adapt to different substrates without requiring extensive modifications.

Customization Options for Diverse Applications

The ability to create custom dies allows manufacturers to produce mats for a range of applications. From intricate designs for promotional items to heavy-duty mats for industrial use, foot mat die cutting machines can cater to various market needs.

5. Improved Safety Features

Safety is paramount in any manufacturing environment. Modern foot mat die cutting machines are equipped with advanced safety features that protect operators from accidents and injuries.

Ergonomic Design for Operator Comfort

The ergonomic design of die cutting machines ensures that operators can work comfortably for extended periods. Features such as adjustable height, easy-to-reach controls, and adequate safety guards contribute to a safer work environment.

Implementing Foot Mat Die Cutting Machines in Your Manufacturing Process

Choosing the Right Machine

To maximize the benefits of foot mat die cutting machines, it is essential to choose the right equipment for your specific needs. Consider the following factors:

- **Material compatibility**: Ensure the machine can handle the types of materials you intend to use.

- **Production volume**: Choose a machine that can meet your production demands without sacrificing quality.

- **Budget considerations**: Evaluate your budgetary constraints and look for machines that offer the best value for your investment.

Integrating into Existing Systems

When incorporating a foot mat die cutting machine into your production line, it is crucial to ensure seamless integration with existing processes.

Training and Development

Provide thorough training for your operators to maximize the machine's capabilities. Familiarization with the machine’s features and safety protocols can significantly enhance efficiency and productivity.

Real-World Applications of Foot Mat Die Cutting Machines

Automotive Industry

In the automotive sector, foot mat die cutting machines are essential for producing high-quality floor mats. These mats not only provide comfort but also enhance vehicle aesthetics and protect interior surfaces from wear and tear.

Commercial Flooring Solutions

Businesses often require customized mats for entrances, workspaces, and safety applications. Die cutting machines enable the production of tailored solutions that meet specific commercial flooring needs.

Industrial Safety Products

Foot mats designed for industrial safety can help prevent slips and falls, making die cutting machines vital in producing mats that enhance workplace safety.

Maintenance and Care for Die Cutting Machines

Routine Maintenance Practices

To ensure longevity and optimal performance of foot mat die cutting machines, regular maintenance is essential. This includes:

- **Cleaning and lubrication**: Keep the machine free from debris and ensure all moving parts are well-lubricated.

- **Calibration and adjustments**: Regularly check and calibrate the machine settings to uphold precision and accuracy.

Common Issues and Troubleshooting Tips

Understanding common issues that may arise during operation can help in troubleshooting. Operators should be trained to identify problems such as cutting inconsistencies and machine malfunctions to minimize downtime.

Future Trends in Die Cutting Technology

Advancements in Automation

As technology continues to evolve, the future of foot mat die cutting machines looks promising. Innovations in automation, such as Artificial Intelligence (AI) and Machine Learning (ML), are set to enhance the precision and efficiency of these machines.

Integration of Smart Technology

The growing trend of smart manufacturing is likely to bring new features to die cutting machines. Enhanced data analytics and IoT connectivity can streamline operations and improve decision-making processes.

FAQs

1. What materials can be cut with a foot mat die cutting machine?

Foot mat die cutting machines can cut various materials, including rubber, foam, textiles, and plastics, making them versatile for multiple applications.

2. How do I choose the right die cutting machine for my business?

Consider factors such as material compatibility, production volume, and budget when selecting a foot mat die cutting machine for your business.

3. What is the average lifespan of a die cutting machine?

With proper maintenance, a quality foot mat die cutting machine can last many years, often exceeding 10 years of reliable service.

4. Are foot mat die cutting machines easy to operate?

While initial training is essential, most modern foot mat die cutting machines are designed for user-friendliness, allowing operators to quickly learn the controls and processes.

5. How can I increase the efficiency of my die cutting operations?

Implementing automation, optimizing machine settings, conducting regular maintenance, and providing training for operators can significantly enhance the efficiency of die cutting operations.

Conclusion

The benefits of using a foot mat die cutting machine are numerous and impactful. With their ability to enhance production speed, ensure precision, and reduce costs, these machines are invaluable in modern manufacturing. As industries continue to evolve, embracing advanced die cutting technology will not only improve operational efficiency but also position businesses for future growth. By investing in foot mat die cutting machines, companies can meet the diverse demands of the market while ensuring high-quality production.

About Us

Specializing in the production of automatic stamping equipment and punching machine peripheral equipment, is a research and development, design, production, sales, maintenance as one of the international precision stamping automation equipment manufacturing enterprises.

Contact Us

Add: Building A, Xiaoxuewei Industrial Park, Shajing, Bao'an District, Shenzhen

WhatsApp: +86 190 9240 6289

E-mail: xiaolisisale1@gmail.com

Related News