Understanding the Role of Insulation Die Cutting Machines in Modern Manufacturing

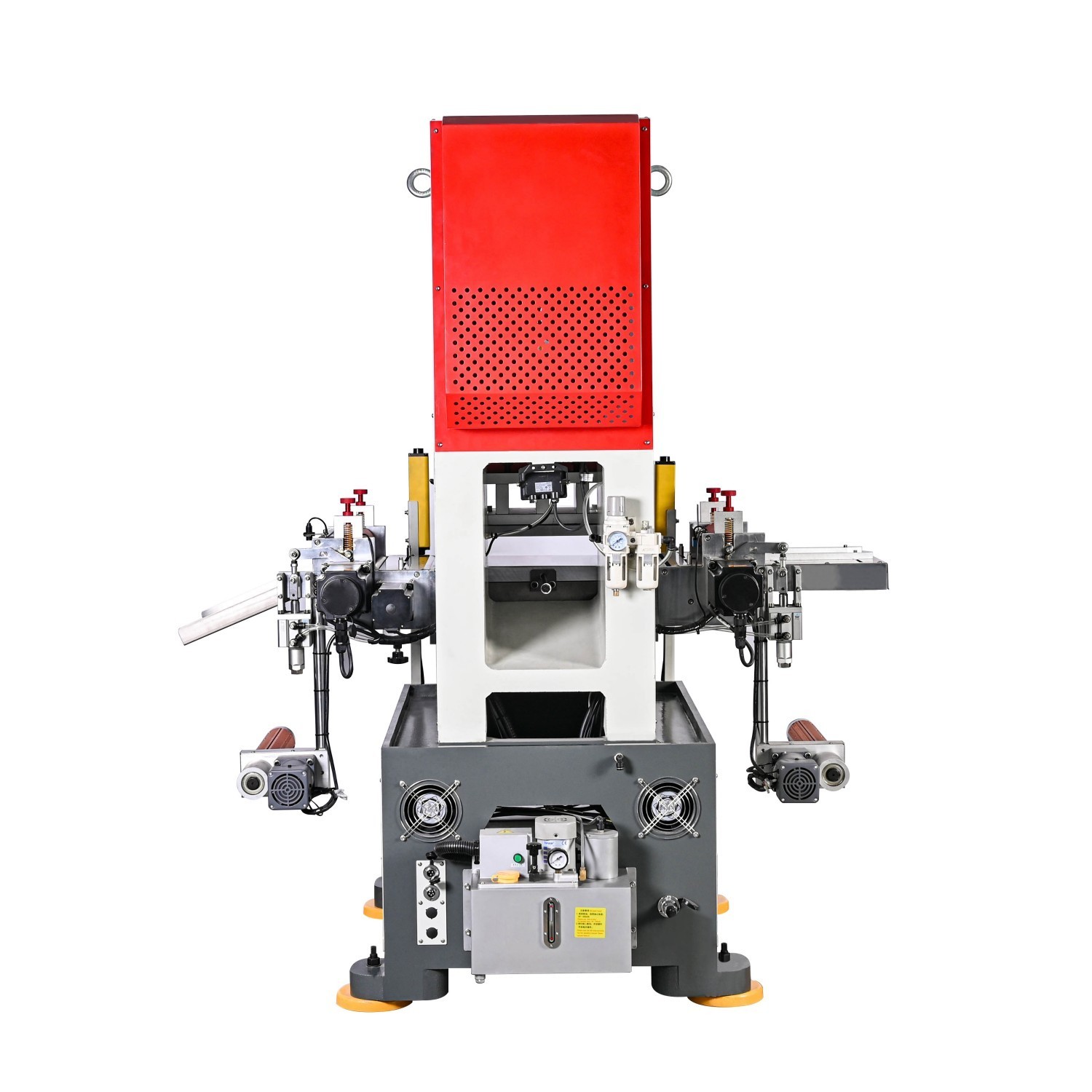

In the manufacturing sector, particularly within the post-processing machinery industry, insulation die cutting machines have become essential tools. These machines are designed to cut various types of insulation materials—such as foam, rubber, and other composite materials—into specific shapes and sizes required for diverse applications. Understanding the functionality and benefits of these machines can significantly impact production efficiency and product quality.

The primary advantage of insulation die cutting machines lies in their precision. Unlike manual cutting methods, which can lead to inconsistencies and waste, die cutting technology ensures that each piece of insulation material is cut to exact specifications. This level of accuracy is particularly important in industries such as construction, automotive, and aerospace, where insulation plays a critical role in energy efficiency and safety.

Moreover, insulation die cutting machines can handle a wide range of materials. From lightweight foams to thicker composites, these machines are versatile enough to accommodate various specifications. This adaptability allows manufacturers to streamline their production processes, reducing downtime and increasing output.

Another significant benefit of insulation die cutting machines is their ability to reduce waste. Traditional cutting methods often result in leftover scraps, leading to material wastage. In contrast, die cutting optimizes the use of raw materials, ensuring that manufacturers get the most out of their investments. This not only enhances cost-effectiveness but also contributes to more sustainable manufacturing practices.

Automation is another critical aspect of modern insulation die cutting machines. Many of these machines are equipped with advanced technology that allows for automated operations. This feature not only speeds up the production process but also minimizes the potential for human error. Operators can set parameters for cutting, and the machine will execute the task efficiently, leading to higher throughput and reduced labor costs.

Furthermore, insulation die cutting machines are often designed with user-friendly interfaces, making them accessible for operators with varying levels of expertise. This ease of use can lead to quicker training times and increased productivity within a manufacturing facility.

As the demand for insulation materials continues to grow, driven by trends in energy efficiency and sustainability, the importance of advanced manufacturing technologies such as insulation die cutting machines cannot be overstated. By investing in these machines, manufacturers can position themselves competitively in the market, ensuring they meet the evolving needs of their customers while maintaining high standards of quality and efficiency.

In conclusion, insulation die cutting machines are pivotal in modern manufacturing, offering precision, versatility, waste reduction, and automation. Understanding their benefits can help manufacturers harness these technologies to improve their production processes, ultimately leading to greater success in the industry.

The primary advantage of insulation die cutting machines lies in their precision. Unlike manual cutting methods, which can lead to inconsistencies and waste, die cutting technology ensures that each piece of insulation material is cut to exact specifications. This level of accuracy is particularly important in industries such as construction, automotive, and aerospace, where insulation plays a critical role in energy efficiency and safety.

Moreover, insulation die cutting machines can handle a wide range of materials. From lightweight foams to thicker composites, these machines are versatile enough to accommodate various specifications. This adaptability allows manufacturers to streamline their production processes, reducing downtime and increasing output.

Another significant benefit of insulation die cutting machines is their ability to reduce waste. Traditional cutting methods often result in leftover scraps, leading to material wastage. In contrast, die cutting optimizes the use of raw materials, ensuring that manufacturers get the most out of their investments. This not only enhances cost-effectiveness but also contributes to more sustainable manufacturing practices.

Automation is another critical aspect of modern insulation die cutting machines. Many of these machines are equipped with advanced technology that allows for automated operations. This feature not only speeds up the production process but also minimizes the potential for human error. Operators can set parameters for cutting, and the machine will execute the task efficiently, leading to higher throughput and reduced labor costs.

Furthermore, insulation die cutting machines are often designed with user-friendly interfaces, making them accessible for operators with varying levels of expertise. This ease of use can lead to quicker training times and increased productivity within a manufacturing facility.

As the demand for insulation materials continues to grow, driven by trends in energy efficiency and sustainability, the importance of advanced manufacturing technologies such as insulation die cutting machines cannot be overstated. By investing in these machines, manufacturers can position themselves competitively in the market, ensuring they meet the evolving needs of their customers while maintaining high standards of quality and efficiency.

In conclusion, insulation die cutting machines are pivotal in modern manufacturing, offering precision, versatility, waste reduction, and automation. Understanding their benefits can help manufacturers harness these technologies to improve their production processes, ultimately leading to greater success in the industry.

About Us

Specializing in the production of automatic stamping equipment and punching machine peripheral equipment, is a research and development, design, production, sales, maintenance as one of the international precision stamping automation equipment manufacturing enterprises.

Contact Us

Add: Building A, Xiaoxuewei Industrial Park, Shajing, Bao'an District, Shenzhen

WhatsApp: +86 190 9240 6289

E-mail: xiaolisisale1@gmail.com

Related News